A pillow block bearing is a mounted bearing used to support a rotating shaft. It consists of a housing and an insert bearing.

Pillow block bearings are essential components in various mechanical systems. They provide support for rotating shafts, ensuring smooth and efficient operation. These bearings are housed in robust structures, designed to handle high loads and reduce friction. Industries such as agriculture, manufacturing, and automotive rely on pillow block bearings for their machinery.

They are easy to install and maintain, offering a cost-effective solution for equipment longevity. Various sizes and materials are available to meet specific application needs. Proper lubrication and regular inspections can enhance their performance and lifespan. Investing in quality pillow block bearings can significantly improve machine reliability.

Introduction To Pillow Block Bearings

Pillow block bearings are essential components in many machines. They support rotating shafts and reduce friction. These bearings ensure smooth and efficient operation. Understanding pillow block bearings is important for machine maintenance.

Definition

A pillow block bearing is a type of mounting bracket. It houses a bearing and provides support for a rotating shaft. Pillow block bearings help reduce wear and tear on machinery. They consist of a mounting block and an insert bearing. The mounting block is usually made of cast iron or steel. The insert bearing fits snugly into the block.

Historical Background

Pillow block bearings have a rich history. They were first used during the industrial revolution. Machines needed reliable ways to support rotating shafts. Early pillow blocks were simple wooden blocks. Over time, materials and designs evolved. Modern pillow block bearings use advanced materials. These improvements have increased efficiency and durability.

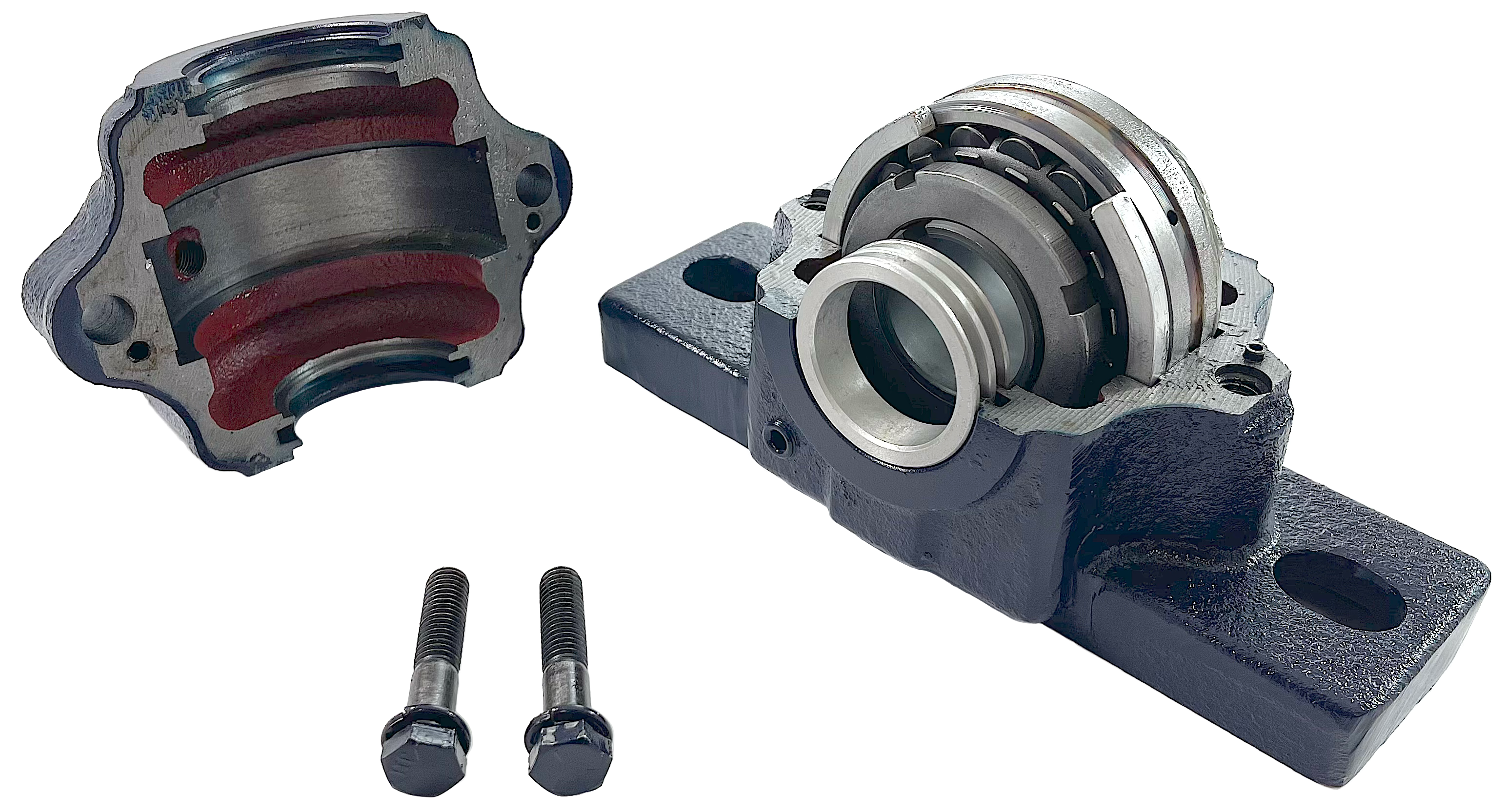

Credit: ph.rs-online.com

Types Of Pillow Block Bearings

Pillow block bearings are crucial in various applications. They support rotating shafts and ensure smooth operation. Understanding the different types can help you choose the right bearing for your needs.

Standard Types

Standard pillow block bearings are commonly used. They come in various designs to meet different requirements.

| Type | Description |

|---|---|

| Ball Bearings | These are versatile and handle both radial and thrust loads. They are easy to install and maintain. |

| Roller Bearings | These can support heavier loads than ball bearings. They are ideal for high-load applications. |

| Plain Bearings | These have a simple design and are cost-effective. They are used for light to moderate load applications. |

Specialized Variants

Specialized pillow block bearings are designed for specific applications. They offer unique features for particular needs.

- Thermoplastic Bearings: Made from durable plastic, resistant to chemicals and corrosion. Ideal for food and pharmaceutical industries.

- Stainless Steel Bearings: Resistant to rust and corrosion. Perfect for wet or humid environments.

- High-Temperature Bearings: Can withstand extreme heat. Suitable for applications involving high temperatures.

Materials Used

Understanding the materials used in pillow block bearings is crucial. The materials directly influence the bearing’s performance and lifespan. Different components of pillow block bearings use different materials. Let’s explore these in detail.

Housing Materials

The housing of a pillow block bearing is vital. It provides support and protection to the bearing. Common materials used for housing include:

- Cast Iron: Known for its strength and durability.

- Pressed Steel: Lightweight and cost-effective.

- Stainless Steel: Offers excellent corrosion resistance.

- Plastic: Suitable for light-duty applications.

Each material has specific benefits. Cast iron is strong and durable. Pressed steel is light and affordable. Stainless steel resists corrosion well. Plastic is good for lighter duties.

Bearing Materials

The bearings inside the housing also use varied materials. These materials impact the bearing’s load capacity and efficiency. Common materials include:

- Chrome Steel: High load capacity and wear resistance.

- Stainless Steel: Resistant to rust and corrosion.

- Ceramic: Lightweight and high-speed capabilities.

- Plastic: Used in low-load, low-speed applications.

Chrome steel offers high load capacity and durability. Stainless steel is rust and corrosion-resistant. Ceramic bearings are light and can operate at high speeds. Plastic bearings suit low-load and low-speed uses.

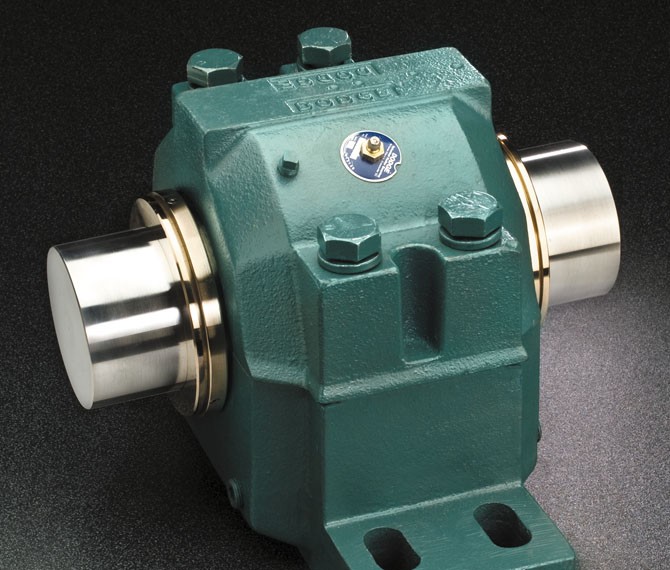

Credit: www.usarollerchain.com

Design And Construction

Pillow block bearings are crucial in providing support for a rotating shaft. They are designed to ensure smooth and efficient operation in various applications. Let’s delve into the design and construction of these essential components.

Components

Pillow block bearings consist of several key components:

- Housing: The outer casing that holds the bearing.

- Insert Bearing: The inner part that rotates.

- Mounting Hardware: Bolts and screws used for installation.

Design Features

Pillow block bearings come with distinctive design features:

| Feature | Details |

|---|---|

| Self-Aligning | Compensates for shaft misalignment. |

| Sealed Bearing | Protects against contaminants. |

| Mounting Ease | Simple installation process. |

These features ensure durability and optimal performance. The design makes maintenance easy. Pillow block bearings are reliable and efficient.

Installation And Maintenance

Proper installation and maintenance of pillow block bearings ensure their longevity and efficiency. This section provides easy-to-follow steps for installing and maintaining these crucial components.

Installation Steps

- Preparation: Gather all necessary tools and materials. Ensure the work area is clean.

- Inspect Components: Check the bearing, housing, and shaft for any damage.

- Position the Bearing: Place the bearing into the housing correctly.

- Align the Shaft: Slide the shaft through the bearing. Ensure it is properly aligned.

- Tighten Bolts: Secure the bearing to the shaft by tightening the set screws.

- Mount the Assembly: Attach the pillow block bearing to its mounting surface.

- Final Check: Rotate the shaft to ensure smooth movement.

Maintenance Tips

- Regular Lubrication: Lubricate the bearing regularly to reduce friction.

- Clean Surroundings: Keep the area around the bearing clean to prevent contamination.

- Inspect for Wear: Check for signs of wear and replace parts if necessary.

- Tighten Bolts: Periodically check and tighten the bolts to ensure stability.

- Monitor Temperature: Keep an eye on the bearing temperature. High heat can indicate issues.

By following these steps and tips, you can ensure your pillow block bearings operate smoothly and last longer.

Common Applications

Pillow block bearings are versatile and widely used in various industries. They provide support for rotating shafts and reduce friction. Here are some common applications:

Industrial Uses

Pillow block bearings are essential in many industrial settings. They support and stabilize heavy machinery. This ensures smooth operation and reduces maintenance costs.

- Conveyor Systems: Used to support conveyor belts in factories.

- Pumps: Ensure efficient operation of water pumps and industrial pumps.

- Fans and Blowers: Provide stability to industrial fans and air blowers.

- Textile Machinery: Support moving parts in weaving and spinning machines.

- Mining Equipment: Stabilize heavy-duty mining machines and tools.

In summary, pillow block bearings enhance efficiency in industrial equipment. They reduce downtime and improve productivity.

Commercial Uses

Pillow block bearings are also used in various commercial applications. They ensure the smooth functioning of everyday machines and devices.

- HVAC Systems: Support fans and motors in heating and cooling systems.

- Food Processing: Used in machines for mixing, cutting, and packaging.

- Automotive: Ensure the smooth running of conveyor belts and lifts in car services.

- Fitness Equipment: Provide support in treadmills and exercise machines.

- Office Equipment: Stabilize moving parts in printers and copiers.

Overall, pillow block bearings are crucial in many commercial sectors. They ensure reliability and efficiency in various machines.

Benefits Of Using Pillow Block Bearings

Pillow block bearings offer numerous advantages for various applications. They provide support and alignment for rotating shafts. Their design ensures smooth operation and longevity. Below, we explore key benefits: Durability and Efficiency.

Durability

Pillow block bearings are known for their durability. They are made from high-quality materials. This construction ensures they withstand heavy loads and harsh conditions. Their robust design reduces wear and tear.

Many pillow block bearings have protective seals. These seals prevent dust and debris from entering. This extends the lifespan of the bearings. Regular maintenance is minimal, making them cost-effective.

Efficiency

Pillow block bearings enhance efficiency in machinery. They reduce friction between moving parts. This leads to smoother and faster operation. Energy consumption is lowered as a result.

These bearings allow for easy alignment adjustments. This feature minimizes downtime during maintenance. They are also easy to install. This saves time and resources during setup.

| Benefit | Details |

|---|---|

| Durability | Made from high-quality materials, withstands heavy loads, minimal maintenance. |

| Efficiency | Reduces friction, allows easy alignment, saves energy, easy installation. |

Troubleshooting And Solutions

Pillow block bearings are essential in many applications. They ensure smooth operations of machinery. Sometimes, issues arise that can disrupt performance. Identifying problems early can save time and money. Below are some common issues and effective solutions.

Common Issues

- Overheating: Bearings get too hot during operation.

- Excessive Noise: Unusual sounds like grinding or squealing.

- Vibration: Increased vibration levels in machinery.

- Misalignment: Bearings not aligned properly with the shaft.

- Lubrication Failure: Lack of or improper lubrication.

Effective Solutions

| Issue | Solution |

|---|---|

| Overheating |

|

| Excessive Noise |

|

| Vibration |

|

| Misalignment |

|

| Lubrication Failure |

|

Future Trends

The world of Pillow Block Bearings is constantly evolving. Future trends will shape the industry significantly. New technologies and market shifts will play crucial roles. Let’s explore these future trends in more detail.

Technological Advancements

Technological advancements will redefine Pillow Block Bearings. New materials will enhance durability and performance. Smart bearings will monitor health and predict failures.

- Integration of IoT for real-time monitoring

- Use of advanced composites for lightweight and strong bearings

- 3D printing for custom and rapid prototyping

These innovations will improve efficiency and reduce downtime. Smart bearings will provide data for predictive maintenance. This will lead to cost savings and longer equipment life.

Market Predictions

The market for Pillow Block Bearings is growing. Emerging markets will drive demand. Key sectors include industrial machinery, automotive, and agriculture.

| Sector | Market Growth |

|---|---|

| Industrial Machinery | 7% annually |

| Automotive | 5% annually |

| Agriculture | 6% annually |

Industrial machinery will see the highest growth. This is due to automation and new manufacturing techniques. The automotive sector will also see significant demand.

Credit: www.inpro-seal.com

Frequently Asked Questions

What Is A Pillow Block Bearing?

A pillow block bearing is a mounted bearing that supports a rotating shaft. It consists of a mounting bracket and a bearing unit.

How Does A Pillow Block Bearing Work?

A pillow block bearing works by providing support to a rotating shaft. It reduces friction and allows smooth rotation.

Where Are Pillow Block Bearings Used?

Pillow block bearings are used in various applications. Common uses include conveyors, fans, and industrial machinery.

What Materials Are Pillow Block Bearings Made Of?

Pillow block bearings are made from materials like cast iron, steel, and plastic. The choice depends on the application.

Conclusion

Pillow block bearings are essential for smooth and efficient machinery operation. They offer durability and ease of maintenance. Investing in quality pillow block bearings ensures long-term reliability. Choose the right type to enhance your equipment’s performance and lifespan. Remember to consult experts for the best fit for your specific needs